The correct configuration of the fire extinguisher and the choice of accessories

A fire extinguisher refers to a fire extinguisher that can spray the filled fire extinguishing agent under the action of its internal pressure to extinguish a fire, and can be moved by manpower for easy access. The task of the fire extinguisher is to fight the first fire. It is widely used in many occasions due to its simple structure, lightness and flexibility, and convenient use. It is a popular fire extinguishing tool that is ideal in actual fire fighting. Therefore, reasonable deployment and use of fire extinguishers play a pivotal role in fighting and controlling the initial fire. Fire extinguisher configuration requirements 1. The number of fire extinguishers in underground buildings should be increased by 30% according to the corresponding regulations on ground buildings; 2. For places with fire hydrant systems, the number of fire extinguishers can be reduced by 30%; for places with fire extinguishing systems, the number of fire extinguishers can be reduced by 50%; for places wi...

view more

How to use various common fire extinguishers

Fire extinguishers are used to extinguish fires. Learning and familiarizing with the use of various common fire extinguishers will help us to solve problems with ease in the face of sudden fire accidents. The following are the use methods of various common fire extinguishers for reference. Lift type dry powder fire extinguisher: Take the fire extinguisher upside down twice to the fire extinguishing site, pull out the safety plug, hold the nozzle with one hand and aim at the flame root, and press the handle with the other hand. When extinguishing a fire, it should be thrown out at one time; when using it outdoors, you should stand at the upper air vent of the fire source, sweep from near to far, and move forward to prevent the flame from running back. Foam fire extinguisher: The fire extinguishing fluid of the foam fire extinguisher is composed of aluminum sulfate, sodium bicarbonate and licorice. When extinguishing a fire, turn the foam fire extinguisher upside down, and the foam can b...

view more

Precautions for replacement of fire extinguisher repair parts

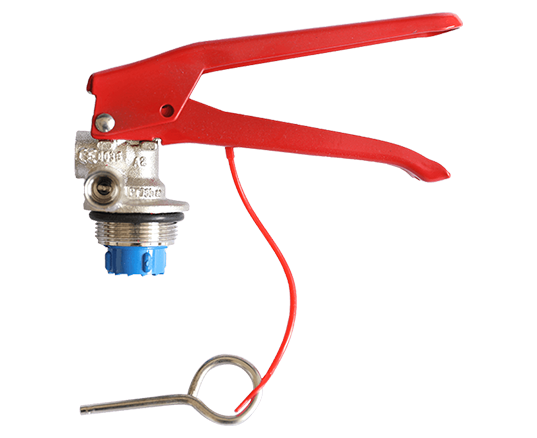

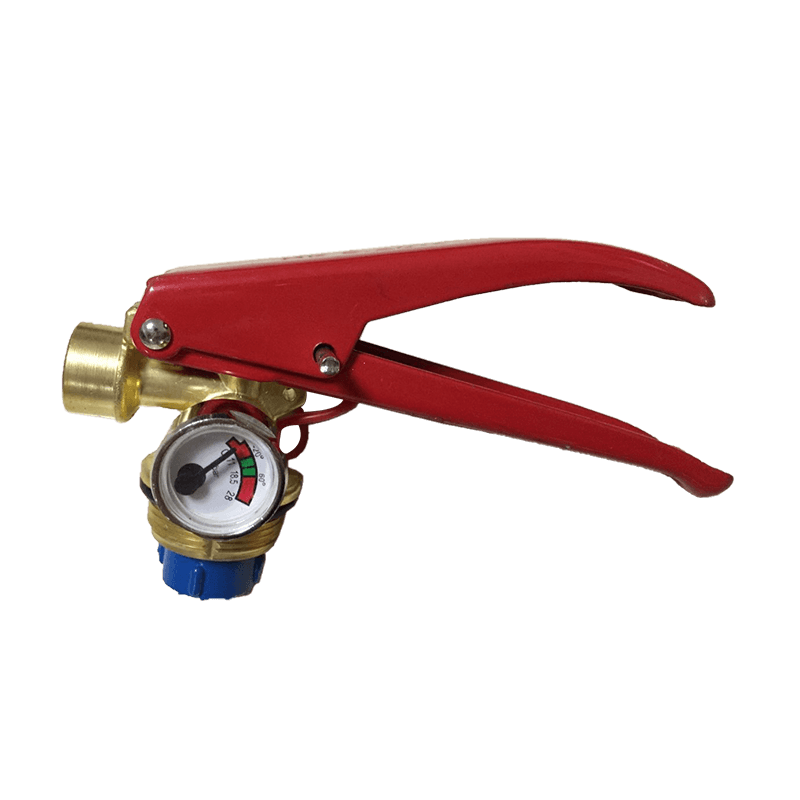

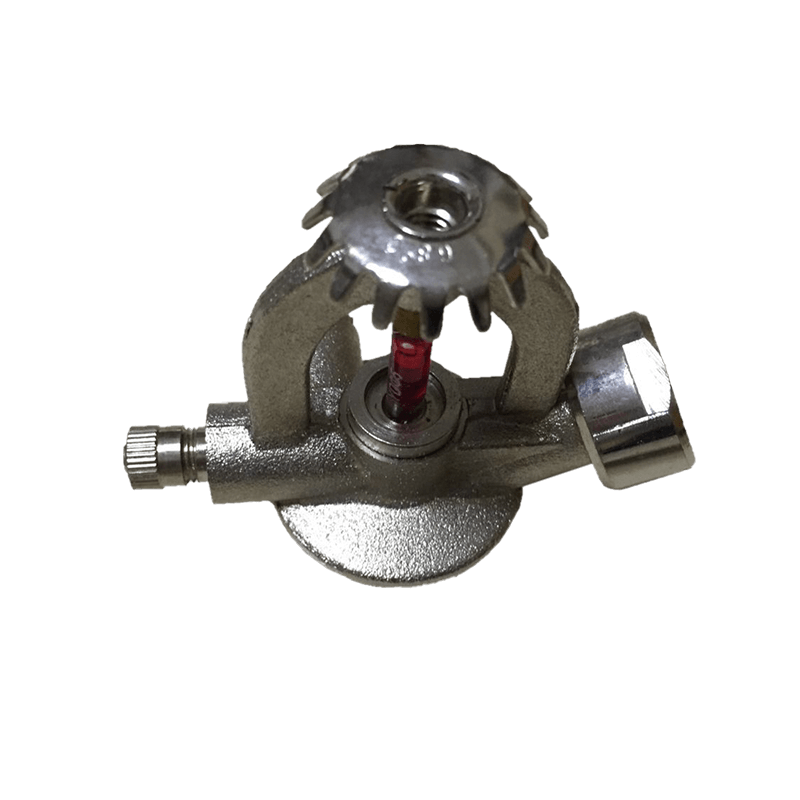

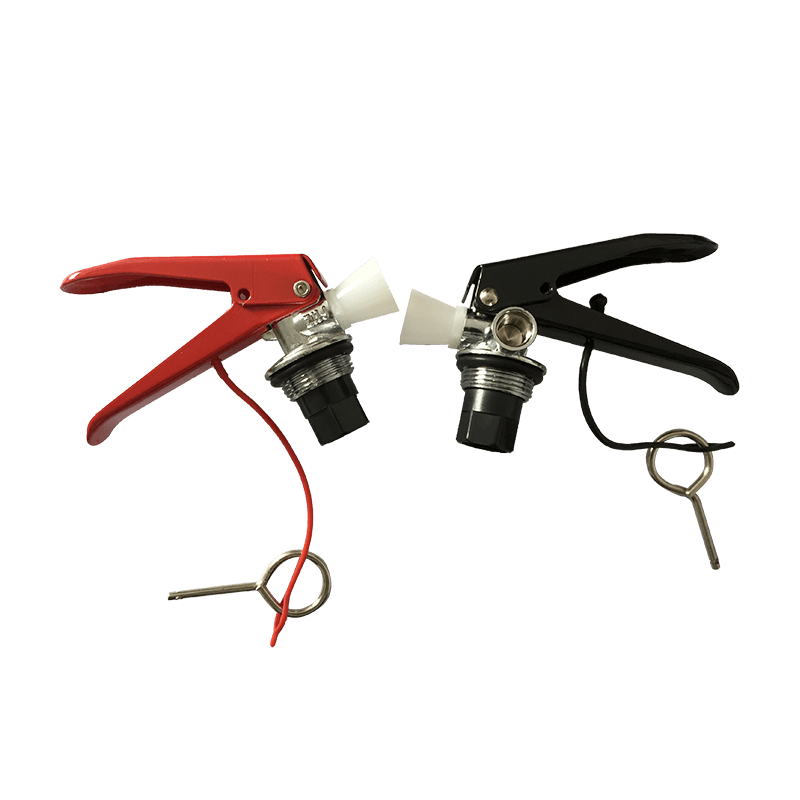

After the fire extinguisher parts are checked, replace the seals and damaged parts of the fire extinguisher, but the barrel and head body of the fire extinguisher cannot be replaced. All parts that need to be replaced should be products of the same model and specifications provided and recommended by the original manufacturer. And should replace and repair spare parts according to the following requirements: (1) The cylinder body that has passed the water pressure test has a complete nameplate and some paint peeling off. Carry out touch-up paint. After touch-up paint, ensure that the paint film is smooth, flat, consistent in color, free of bubbles, flow marks, wrinkles, etc., and the paint must not cover the nameplate. (2) Replace the deformed, discolored, aged or broken rubber and plastic parts; replace the sealing parts such as seals and gaskets to ensure compliance with the sealing requirements. 3) Replace the pressure indicator that has the defects of outer surface deformation, dam...

view more

What kind of valve is the multifunctional water pump control valve?

What kind of valve is the multifunctional water pump control valve? In fact, the multifunctional water pump control valve is composed of a main valve, a regulating valve and a pipe connection system. The valve body adopts a direct-flow valve body, and the main valve control room is a diaphragm type or a piston type. Double control room structure, the control room has one more than the general hydraulic control valve, which increases the control function of the main valve, and realizes the slow opening, full opening, slow closing, cut-off and other multi-function control of the water pump outlet, and the realization of a valve , One-time adjustment of the multi-function control of the pump outlet. This product is used in the pump outlet pipelines of high-rise building water supply systems and other water supply systems to prevent and weaken the water hammer and water hammer of the pipeline when the pump is opened and closed, prevent water backflow, protect the pump, and maintain the pip...

view more

What should be paid attention to when installing and using the regulating valve?

In the field use of regulating valves, many of them are not caused by the quality of the regulating valve itself, but caused by improper installation and use of the regulating valve, such as the installation environment, improper installation position and direction, or unclean pipelines. Therefore, the following aspects should be paid attention to when installing and using the electric control valve: (1) The regulating valve is a field instrument, and the ambient temperature should be in the range of -25~60℃, and the relative humidity should be ≤95%. If it is installed in the open air or in a high-temperature place, waterproof and cooling measures should be taken. Keep away from the vibration source or increase anti-vibration measures where there is a seismic source. (2) The regulating valve should generally be installed vertically, and can be tilted under special circumstances. For example, when the tilt angle is large or the valve itself is too heavy, the valve should be protected by...

view more

How to deal with the failure of the electric control valve?

Electric regulating valve is a regulating valve that uses power to drive an electric actuator and then a valve to throttle. It is an important executive unit instrument in industrial automation process control. With the increasing degree of automation in the industrial field, it is being used more and more in various industrial production fields. Compared with the traditional pneumatic control valve, the electric control valve has obvious advantages: energy saving (consumption of electricity only when working), environmental protection (no carbon emission), quick and convenient installation (no need for complicated pneumatic pipelines and air pump workstations) : AC22V 380V and other voltage levels. Fault 1: The actuator does not work, but the power supply and signal lights of the control module are on. Solution: Check whether the power supply voltage is correct; whether the motor is disconnected; whether the ten-core plug is disconnected from the end to the end of each line; whether t...

view more

How to classify electric stainless steel ball valves according to their structure?

Electric stainless steel ball valve is also a branch of stainless steel valve because the material is stainless steel. Electric stainless steel ball valve has many functions, wide application range and strong adaptability. Because stainless steel material is corrosion-resistant and wear-resistant, it is very popular. I also think that the classification of electric stainless steel ball valves is more detailed, so it is not difficult for many manufacturers to choose the electric stainless steel ball valve that suits them, so it is a big step in efficiency. Electric stainless steel ball valves are divided into floating ball valves, fixed ball valves, and elastic ball valves according to their structure. These three electric stainless steel ball valves have certain differences. For details, please refer to the corresponding concepts for your own analysis: The ball of the floating ball valve is floating. Under the action of the medium pressure, the ball can produce a certain displacement a...

view more

What are the characteristics of Class I fire extinguishers?

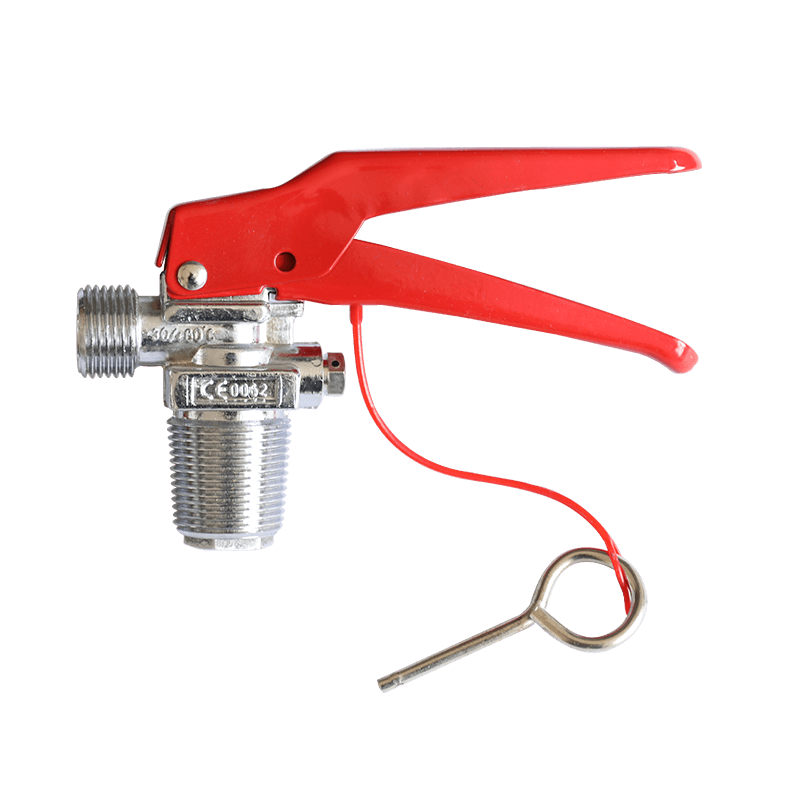

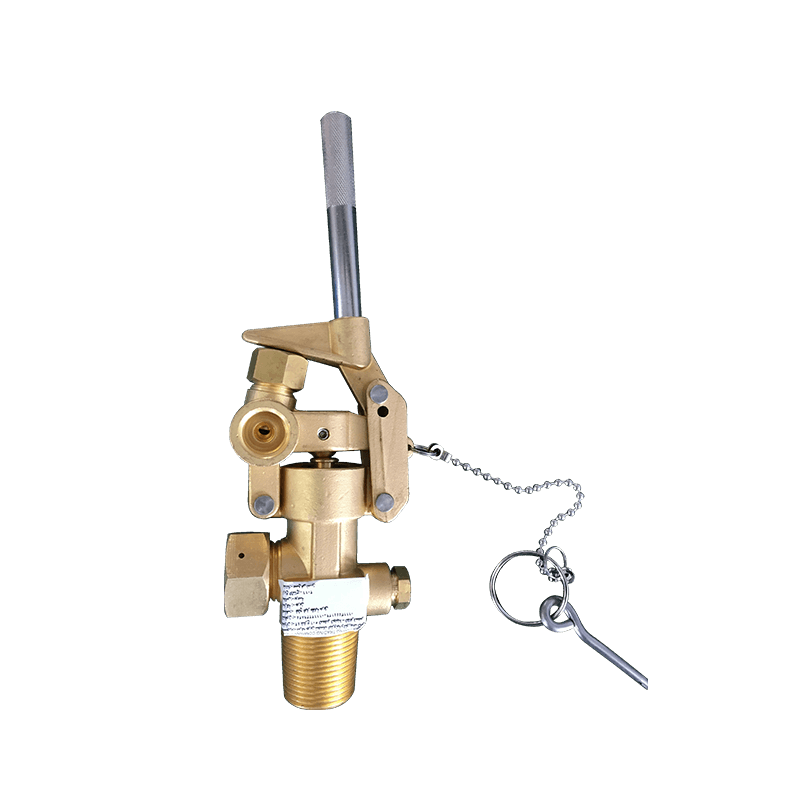

Fire Extinguisher Valves are very important part of fire safety equipment. These are used to control the spread of flames in confined spaces like the kitchen, work place or the attic. These can also be used to extinguish flames in open spaces like a big garden, courtyard or any open space where there are inflammable materials. It is important to place these at points of entry and exit for the safety of the people near the area. They protect people from serious injuries or damage if an accident occurs. There are different types of fire extinguishers depending upon their use and purpose. The common fire extinguisher valves available in the market consist of three main parts, which are the handle, a body and a cover. The handles are made of rubber and have a metal frame with a spring mechanism to enable easy control. The body is made up of nylon and has an opening for the release of the fuel and the cover is made of polypropylene. The price of each type depends upon the weight and the siz...

view more

The difference between brass valve and bronze valve

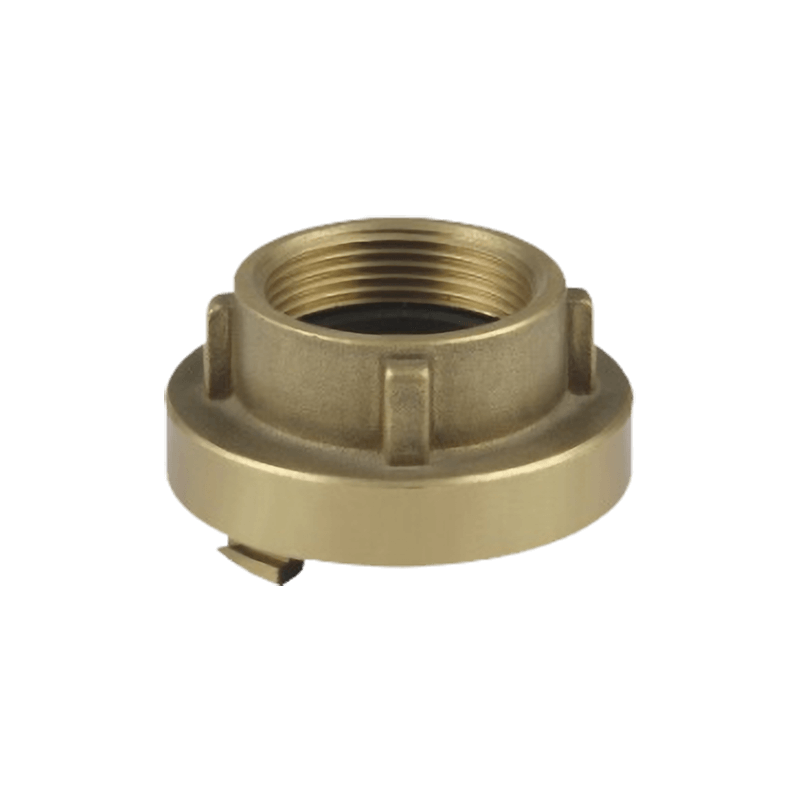

According to different compositions, copper alloys are divided into brass and bronze. Adding certain alloying elements (such as zinc, tin, aluminum, beryllium, manganese, silicon, nickel, phosphorus, etc.) to pure copper forms a copper alloy. Copper alloy has good electrical conductivity, thermal conductivity and corrosion resistance, as well as high strength and wear resistance. 1. Brass is a copper alloy with zinc as the main alloying element. According to its chemical composition, brass is divided into two types: ordinary copper and special brass. (1) Ordinary brass Ordinary brass is a binary alloy of copper and zinc. Due to its good plasticity, it is suitable for the manufacture of plates, bars, wires, pipes and deep-drawn parts, such as condenser tubes, radiator tubes and mechanical and electrical parts. Brass with an average copper content of 62% and 59% can also be cast and is called cast brass. (2) Special brass In order to obtain higher strength, corrosion resistance and good ...

view more

简体中文

简体中文 English

English